Introduction

In today’s fast-changing world of materials, coatings, and technology, UVLACK has become a buzzword in multiple industries. From protective coatings to industrial applications, UVLACK represents a new generation of solutions designed to make surfaces stronger, more durable, and resistant to the challenges of everyday life.

But what exactly is UVLACK? How does it work? And why are so many companies and individuals turning to it? In this detailed guide, we’ll explore UVLACK in depth, covering its meaning, importance, benefits, applications, and future potential.

What Is UVLACK?

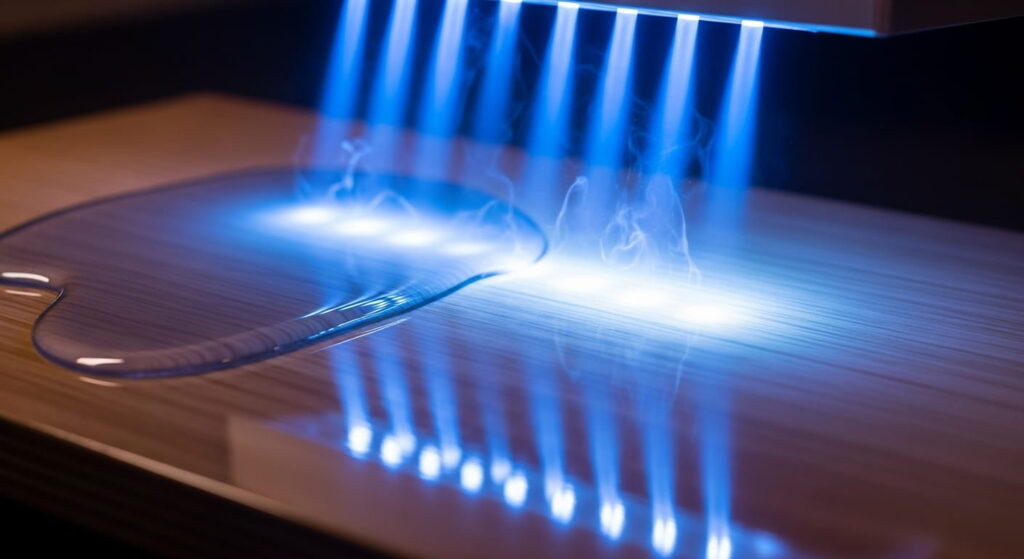

At its core, UVLACK refers to a specialized type of coating that is cured or hardened using ultraviolet (UV) light. Unlike traditional paints or finishes that rely on heat or air-drying, UVLACK transforms into a strong protective layer when exposed to UV radiation.

This curing method allows for:

- Faster application times.

- Stronger and more resistant finishes.

- Eco-friendlier processes compared to solvent-based coatings.

The word itself combines “UV” (ultraviolet) with “LACK” (a term commonly used in European languages for lacquer or coating), showing its strong link to modern finishing and surface-protection industries.

Why UVLACK Matters Today

Modern industries face a major challenge: creating materials that are long-lasting, stylish, and environmentally friendly. Traditional paints and coatings often release harmful solvents into the air, take hours or even days to dry, and may not withstand long-term exposure to sunlight, chemicals, or scratches.

This is where UVLACK makes a difference. By using ultraviolet curing technology, UVLACK offers:

- Durability: Surfaces become highly resistant to scratches, chemicals, and fading.

- Speed: UV curing is extremely fast, often taking just seconds.

- Sustainability: It reduces harmful emissions and is safer for the environment.

- Versatility: It can be applied to a wide range of materials, from wood to plastics to metals.

Key Benefits of UVLACK

Here are some of the most important reasons why UVLACK is gaining global attention:

1. Superior Durability

UVLACK coatings are tougher than conventional coatings. They resist scratches, stains, and abrasions, making them perfect for high-traffic areas or products that endure heavy use.

2. Quick Curing Time

Traditional coatings can take hours or even days to fully harden. With UVLACK, curing happens in seconds under UV light, making production faster and more efficient.

3. Environmentally Friendly

Since UVLACK doesn’t rely on large amounts of solvents, it emits fewer volatile organic compounds (VOCs). This makes it a cleaner, greener option compared to traditional coatings.

4. Aesthetic Appeal

UVLACK provides a sleek, glossy finish that enhances the look of any surface. It can also be customized for matte or satin effects depending on design needs.

5. Cost Efficiency

Though the initial equipment for UV curing might be expensive, the long-term benefits—less waste, faster production, and fewer defects—make UVLACK a cost-effective solution.

Where Is UVLACK Used?

UVLACK has wide-ranging applications across industries. Let’s explore the most popular ones.

1. Furniture and Woodwork

One of the most common uses of UVLACK is in wooden furniture. It gives wood a glossy, protective finish while keeping its natural look intact. Dining tables, cabinets, and floors benefit from its scratch resistance.

2. Automotive Industry

Car manufacturers use UVLACK for protective coatings on both interiors and exteriors. It keeps paint vibrant, resists weather damage, and adds an elegant shine.

3. Electronics and Gadgets

Smartphones, laptops, and wearable devices often rely on UVLACK coatings for scratch resistance and a polished finish that withstands daily handling.

4. Packaging Industry

High-end packaging for cosmetics, electronics, and luxury items frequently uses UVLACK for its glossy and premium feel.

5. Healthcare and Medical Devices

UVLACK is applied to medical instruments and surfaces to ensure durability, resistance to chemicals, and easy cleaning.

6. Industrial Applications

Factories use UVLACK for flooring, machine components, and protective panels where toughness and resistance are essential.

Top 10 Reasons to Choose UVLACK

To summarize its appeal, here are ten strong reasons why businesses and consumers prefer UVLACK:

- Long-lasting surface protection.

- Quick drying and curing process.

- Eco-friendly with lower emissions.

- Resistant to chemicals and UV light.

- Enhances product appearance.

- Reduces maintenance costs.

- Works on multiple surfaces.

- Available in matte, satin, or glossy finishes.

- Increases product value.

- Reliable for both industrial and personal use.

How UVLACK Works: The Science Explained

UVLACK coatings contain special molecules known as photoinitiators. When exposed to ultraviolet light, these molecules trigger a chemical reaction that causes the liquid coating to solidify instantly.

This process is known as UV curing and has several advantages over conventional curing:

- Speed: Takes seconds instead of hours.

- Strength: Creates a tightly bonded finish.

- Precision: Can be applied in controlled layers for specific needs.

Challenges of UVLACK

While UVLACK offers many advantages, it isn’t perfect. Some challenges include:

- Initial Cost: Setting up UV curing equipment can be expensive.

- Limited Penetration: UV light can only cure surfaces that it directly reaches.

- Material Sensitivity: Not all materials respond well to UV curing.

However, as technology improves, many of these limitations are being addressed.

The Future of UVLACK

The future looks bright for UVLACK, especially with industries focusing on sustainability and efficiency. Experts predict that demand will grow in:

- Green buildings and eco-friendly construction.

- Next-gen electronics with ultra-thin coatings.

- Medical equipment that requires hygienic, durable finishes.

- Luxury packaging and branding.

As UV curing technology evolves, UVLACK will likely become more accessible, affordable, and versatile.

Practical Tips for Using UVLACK

For businesses or individuals interested in using UVLACK, here are some practical suggestions:

- Choose the Right Equipment: UV lamps or LED curing systems are essential for proper application.

- Surface Preparation: Clean and smooth surfaces ensure the best results.

- Test Samples First: Before large-scale application, test on small samples.

- Safety Precautions: UV light can be harmful, so protective gear should always be used.

- Work with Experts: Partnering with professionals ensures correct application and long-lasting results.

Interesting Facts About UVLACK

- UV curing technology has been around since the 1960s but has only recently gained mainstream use.

- Some UVLACK finishes can last over 10 years without fading or cracking.

- The global UV coatings market is expected to surpass $10 billion by 2030.

- UVLACK reduces energy consumption by eliminating the need for large ovens or heat-based drying.

- Major industries like automotive and packaging are investing heavily in UVLACK research.

Conclusion

UVLACK is more than just a coating—it’s a breakthrough technology that combines durability, speed, beauty, and eco-friendliness. From protecting furniture and cars to enhancing electronics and packaging, UVLACK is changing how industries think about finishes and surfaces.

As the world continues to move toward sustainability and efficiency, UVLACK stands out as a forward-looking solution with immense potential. Whether you’re a manufacturer, designer, or consumer, understanding and embracing UVLACK can open new opportunities for innovation and long-lasting quality.